Let's see what we'll talk about in this article :

- Fireplace makes house smoky

- Chimney draft problems

- A well built chimney pot

- External air intake

- Chimney draft inducer

- The wind fireplace blower

- Chimney spinner cowl

- Wind directional chimney cap

Fireplace Fills The House With Smoke

A smoky fireplace is one of the setbacks – a very common one, unfortunately – whose cause is the result of several contributing factors: we said that the main suspect is the chimney, but we should never forget about the “human factor”.

What do we mean by "human factor”?

Without hiding, we sincerely have to say that, even before the structural flaws, our choices come first, and they have a bearing on it.

Sometimes, we might fall in love with a fireplace, perhaps a little too big for our house, without considering the side effects this choice may entail.

In other cases, we let ourselves lure by unprofessional sellers who, by complying with our wishes, are happy to sell us a chimney, at a quite high price, perhaps without letting us notice some details, or by lessening its real value.

When you decide to buy a new fireplace, the first thing you have to do, even before browsing through catalogues or visiting shops, is have a clear idea of how the chimney is made, and how our house is structured.

The chimney and the fireplace are two inseparable elements. Even if they are sold separately, if they don’t have the right “feeling", if they don’t reach the perfect harmony, they will give very little from that satisfaction that led us to buy.

So, before taking any decision, let’s stop to reflect and remember that the picture of us, sitting in our armchair in front of a fireplace, with our legs covered by a blanket while watching, hypnotized, the flickering flames, could be real only thanks to the logical and scientific measure by which we consider the problem of how to structure our next fireplace as best as possible.

The forced draft occurs when, while lighting the fireplace, there’s a natural air circulation between the rising hot column (which communicates with the outside through the flue and the cap) and the resulting cold air which descends into the empty space. If this process is hindered in any point, the forced draft is no longer optimal and the smoke will leak out.

If the fireplace does not draw, there can be different reasons. Let’s try to sum them up:

- A wrong design of the flue

- A badly-designed chimney cap

- Some factors which are not related to the building

- Lack of external air scoop

Dealing with Chimney Draft Problems

Now we are going to analyse each element, in order to understand the critical points and their potential solutions; let’s begin with the flue. Carry on with the reading.

The flue is nothing but the conduit which allows the smoke emission, by connecting the fireplace with the outdoor space.

The flue is nothing but the conduit which allows the smoke emission, by connecting the fireplace with the outdoor space.

The forced draft of the flue is caused by the fact that, while lighting the fireplace or the stove, there’s a natural circulation between the column of hot air which goes up through the chimney, and the cold air which goes down towards the resulting empty space.

Some people think that a flue has to guarantee a correct forced draft – regardless of the fact that it is placed inside or outside the house - and the fact that if the flue opens out onto one side of the hipped roof it will not affect the forced draft itself. This is not correct, and that’s why, even inside the same house, there might often be some flues which draw well, and other ones which do not, even though they have the same features: same length, same material, same section.

Summertime, when it’s easier to accomplish masonry and monitoring work with less urgency, is the best period to design the fireplace for the next winter and to change and improve the flue, so that we are sure that everything will work perfectly and at the right time.

There are different materials and shapes of flues. So far, we can reasonably say that stainless steel is one of the best materials and that a circular section is the best shape for pipes.

Steel, due to its smoothness, offers less resistance to smoke passage, whilst the circular section makes the smoke arrange evenly throughout the inner surface of the chimney.

There are also some flues made of other materials, such as refractory ceramic, and of different shapes like a square or a rectangle. But it’s better (necessary, actually) that the inner edges are as rounded as possible, because they are always a critical point for the accumulation of soot and corrosion.

The forced draft is linked to the section and the height of the chimney, which must be well-proportioned to the fireplace size as well.

In order for a flue to draw properly, it also needs to possess some essential requirements:

- No constrictions or abrupt changes in direction

- An adequate section

- To be effectively insulating

- To be sufficiently long

Let’s analyze each one of them.

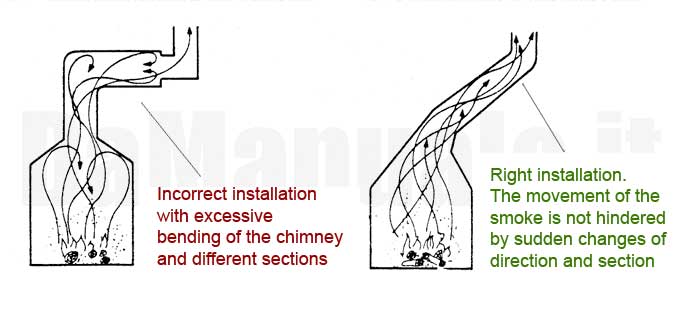

The changes in direction of the flue should never exceed 45° (better if 30°).

The best solution would be a perfectly straight flue but, for a lot of reasons, this is rarely a feasible possibility.

The picture below perfectly conveys the idea of how the chimney should follow more gentle changes as possible.

The flue must be perfectly adapted to the fireplace size.

Having constrictions inside the chimney means creating some turbulences in the emission smoke.

The flue section is also linked with length; going back to the example of a fireplace installed in an attic, we should enlarge the flue section in order to compensate its small length. The longer the flue is, the smaller (to a certain extent) the section can be.

The flue insulation is fundamental to avoid that the smokes cool down during their rising phase and that their emission slows down, making them leaking out of the fireplace.

Mineral wool is the most common insulation material for the steel flues. It is clear that the more centralized the flues are, the better will be their natural insulation, since they will be less exposed to the cold outside.

When the flues are located on perimeter walls, they are more problematic and, even more so, when their construction outside the perimeter walls is mandatory.

There are double-layered steel flues with an insulating material placed inside the gap between the two walls, but their choice must be made for last. First of all, because the double-layered pipes in stainless steel are quite expensive; secondly, because their insulation can never be compared to the insulation of a flue placed inside perimeter walls.

The flue should be long enough to contain potential smoke returns, and its length should not be lower than 3 meters. The longer the flue is, the better the forced draft will be.

It’s clear that if we want to install a fireplace inside an attic, a long flue might be quite hard to build, therefore we must take into account the fact that a gust of wind might push the smoke back more easily.

A Well Built Chimney Pot

A Well Built Chimney Pot

The chimney cap is the final part of the flue, which opens out onto the hipped roof.

The chimney cap is another important factor in determining a good or bad draft of the chimney.

Since the chimney cap is the external part of the flue, it is naturally exposed to the elements and, more importantly, to the intensity and direction of winds.

The chimney cap must be covered in order to prevent rain or snow from entering inside the flue up to the fireplace, by putting the fire out; also, it should be designed properly, so that the wind itself does not penetrate inside by pushing the smoke back.

There are very different chimneys on the market and in this article we’ll present only a few of them. Chimney caps are usually made of masonry (stones, bricks or prefabricated materials), but they can also be made of copper, steel or earthenware tile, ready to be installed.

In earlier times, construction workers were really good at building chimneys with half tiles and, sometimes, the old ones were also pleasing to the eye and efficient against wind.

Prefabricated materials – which are used more often today, combined with different modules creating horizontal cracks for the smoke emission – are not too unaesthetic and, first and foremost, they are the result of a long research of how to guarantee the best smoke outflow as possible.

Usually, the width of the chimney cap should be doubled compared to the section of the flue, and its opening should be located at a meter above the roof level at least.

Unfortunately, this recommendation cannot always be followed because it will be necessary to build a very high chimney to reach the top of the roof, especially if the flue is above the perimeter walls of the building; also, apart from being not exactly the best option from an aesthetic point of view, it is more exposed to strong winds and therefore, more potentially fragile; as a result, it somehow needs to be reinforced.

The chimney cap should also be located at least at ten meters away from all those obstacles which could tower it, such as the walls of near houses, trees, etcetera.

External Air Intake

In very windy places, where the wind flows usually come from the same direction, building “asymmetrical” chimneys could be useful, if oriented towards a favourable direction.

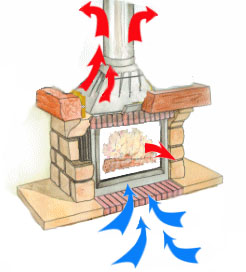

In order to have an optimal forced draft, it is necessary that the cycle between the hot air coming in and the cold air coming out of the chimney is always maintained as such.

In order to have an optimal forced draft, it is necessary that the cycle between the hot air coming in and the cold air coming out of the chimney is always maintained as such.

Combustion creates smoke that needs to be cleared through the flue; the cold air will have to compensate for the air consumed by the flame and therefore foster the combustion process.

When the flow of air is interrupted, or when is not enough to guarantee a balance between the air coming in and the air coming out, combustion becomes a hard process and the room tends to fill up with smoke.

A very common fact is when a chimney draws well at first, but then, after a while, it starts smoking; this is an obvious sign that the air needed to combust is running out, and that something inside the inner/outer air flow is not working properly.

When you buy a new fireplace (for instance, a single-piece one), you can see that the required diameter for the flue and the external air scoop are both indicated.

When the fireplace has not been designed with the house itself, a lot of problems often arise: not only to have an adequate flue, but also to have an external air scoop able to maintain an optimal combustion process.

When a new fireplace is installed, the best solution would be that the cold air coming from outside would be funnelled into the fireside itself; unfortunately, this is not always possible, especially when we install a fireplace inside a house which was not designed for that.

However, if it’s not possible, you cannot exempt yourself from creating a breach on a perimeter wall, which allows the fresh air to come in, while restoring the airflow equilibrium inside the space where the fireplace is located.

On the other hand, if we had built a fireplace in the most inner part of the house without placing it against one of the perimeter walls, we would have faced another problem: the necessity of putting an air scoop far from the fireplace itself, with the consequence that, before reaching the fireside, cold air will invade the entire space whilst reducing the energy efficiency of the fireplace and creating discomfort for those who are inside, with cold sensations at floor level.

However, this is the only feasible solution, unless it would be possible to create an air pipeline (for example, at chimney level), next (and obviously detached) to the flue itself; this solution can be clearly adopted if the flue (and its relative chimney pot) is built from scratch, or at least it can be taken into account if the funnel with a pre-existing flue is wide enough to create some space for an external air scoop.

Always regarding air circulation, there are other reasons that might cause a fireplace malfunction, such as the presence of two different flues inside the same place or an open staircase communicating with the upper floors. In these cases, certain phenomena of air depression might occur, therefore it is appropriate (as long as it is possible) to:

- close the staircase, by building a special wall with a door which guarantee, apart from the best force draft, that heat will not excessively disperse inside the stairwell, to the detriment of the place where the chimney is located.

- close the opening of the additional flue by sealing it accurately.

So far, we’ve seen how to build a fireplace and a flue with the best features, in order to always have the best natural forced draft for the chimney.

So far, we’ve seen how to build a fireplace and a flue with the best features, in order to always have the best natural forced draft for the chimney.

However, in some extreme situations, any modification can be implemented and, with potential smoke returns, the only thing to do is relying on solutions that make the chimney draw even against its will.

The solutions we are going to illustrate are basically applied at the chimney cap level, and they compensate for all those cases in which descending winds or a low air pressure push the smokes back.

Maybe describing all three of these cases as “forced draft” might not be the right choice, but regardless of that, they are extra tools which are going to improve the natural draft of the chimney.

Chimney Draft Inducer

An electric chimney fan is perhaps the most effective and forced solution, because it consists in drawing the chimney fumes even when the flue has some structural flaws which do not allow a proper emission towards the outside.

It doesn’t mean that it must be used as a means to bypass the other problems. If a flue is dirty, forcing the draft procedure with an electric fan could lead, for instance, to a lack of cleaning, until there’s a risk that the flue itself might catch fire.

It doesn’t mean that it must be used as a means to bypass the other problems. If a flue is dirty, forcing the draft procedure with an electric fan could lead, for instance, to a lack of cleaning, until there’s a risk that the flue itself might catch fire.

The electric chimney fan has a very low energy, as well as the benefit that it can be deactivated when necessary: if, for instance, our chimney does not draw well in a particularly windy day, we can activate the fan, and turning it off the other days. In this way, when deactivated, it will not hinder the natural emission of smokes.

As we can notice from the picture on the right, the fan device is a particular structure which replaces the final part of the cap by saving the style of prefabricated terminals, with not inconsiderable aesthetic results.

The superior section above the fan can be customised further by removing the original roof and building on the support base of the engine: it can bear a weight of up to 200 Kg, a structure which suits our building for the best.

The terminal is adjustable, so that it can be modified according to the different sizes of chimneys, which can be both squared and rectangular.

As you can see from the video below, the fan installation procedure is very easy and, once put above the flue, it only needs to be connected to a power source through an extension cable going from the cap up to the electrical box, which is usually placed near the chimney hood.

Wind NILA system

Now let’s move on to another innovative system, used to force the flue draft: the wind and the electric fireplace blower.

The wind fireplace blower differs from the electric blower because it does not work by extracting the fumes, but rather by creating a depression through the Venturi effect inside the flue, so that it cannot allow the smoke to flow back towards the chimney due to descending winds.

The wind fireplace blower differs from the electric blower because it does not work by extracting the fumes, but rather by creating a depression through the Venturi effect inside the flue, so that it cannot allow the smoke to flow back towards the chimney due to descending winds.

The wind blower is a patent from the company Mazzocchi Giampaolo, and it is also available in an electric version, in order to solve those draft problems which do not derive directly from the flows of descending winds.

The originality of the wind blower consists in taking advantage of the wind that, when descending, cause several problems to the smokes flow, and it can neutralize this inconvenience.

This device is made up of a fan system which is wind-powered from the chimney cap, and generate a flow of air which, at first, is pushed inside the inner part of the flue; then, it is expelled from the pipe itself, by being bent to the top and creating an air flow which is pushed towards the chimney outlet.

The picture at the beginning of the article shows the above-mentioned mechanism.

Since the system is wind-powered, it won’t work without wind. However, if the fume malfunction was due to descending winds, it shouldn’t be a problem in case of lack of wind.

For the most serious problems, you can adopt the same system but, this time, it will be electric-powered.

The advantage of Nila electric blower is that it can be installed on any type of chimney without modifying its structure and aesthetic. It has an electric-powered fan, placed on the chimney cap and bent towards the hipped roof and, for this reason, is completely invisible.

The advantage of Nila electric blower is that it can be installed on any type of chimney without modifying its structure and aesthetic. It has an electric-powered fan, placed on the chimney cap and bent towards the hipped roof and, for this reason, is completely invisible.

There’s a pipe, going up to the external part of the chimney cap; the pipe starts from the exhaust vents and then it goes down towards the inner part.

The structure is well-represented by the picture here on the right.

Thanks to this method, the chimney cap is basically made windproof, by increasing the velocity of fume extraction towards the outside.

Lastly, the installation is very simple and suitable even for the skilled DIYer.

The video here below explains, in a very easy way, all the installation phases of the electric model and its mode of operation.

In case you don’t want to see the metallic pipe outside the chimney cap, you can also decide to make a hole on the side of the cap itself. However, for this last case, the procedure is a little bit more complex.

For further information and contacts, please visit the official website: www.nilasystem.it

Chimney Spinner Cowl

Chimney Spinner Cowl

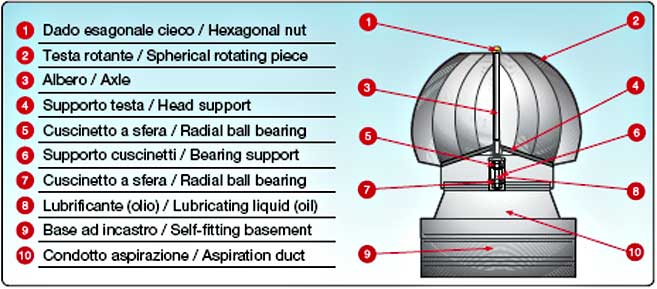

The Chimney Spinner Cowl in stainless steel is one of the best solutions for the smoke leak problem.

These types of chimney caps have been on market for a long time and, as the previously-mentioned solutions, they are essential to avoid that the descending wind, while entering the flue pipe, pushes combustion fumes back.

The wind chimney caps are connected to the final part of the chimney – the masonry ones too – and they are both waterproof and windproof.

They are usually produced in three different materials: zinc-plated metal, stainless steel, copper.

If you have to choose one of these three materials, stainless steel or copper are the best options because they are less vulnerable to the fume corrosion than zinc-plated metal; however, we are talking about a lot of years, and much of it depends also on usage frequency and the geographic zone: corrosion phenomena are more noticeable in humid and foggy areas, exactly because the humidity particles, by combining with the smoke, tend to stay attached to the chimney cap.

Another important aspect we need to check when choosing a rotating wind chimney cap is related to the noise made during rotation.

These caps are clearly activated by wind and, the stronger the wind, the greater the velocity of rotation will be. Therefore, the rotation mechanism must be solid and silent at the same time.

In the picture below you can observe the structure of a wind chimney cap and how the main rotation mechanism is based on the usage of ball bearings and lubricating oil which reduce friction and therefore, noisiness.

For further information, please visit the website of one of the most famous companies: http://www.perfetto.it

Wind Directional Chimney Cap

Let’s finish with some examples of windproof and smokeproof chimney caps in stainless steel:

- Air blower

- Smokeproof terminal

- Windproof chimney cap

Flue system science is in constant evolution, even though it may seem, from the outside, a field where innovation is clearly not a key factor.

Actually, there are a lot of companies that keep testing different, innovative solutions, in order to guarantee that the forced draft of our fireplaces is always the best, in any weather condition.

We’ve already talked about rotating wind chimney caps, and how they use wind movement to activate the draft. A critical point of these terminals is the fact that they possess certain moving parts which, in some cases, can be subject to noise as well as wear and tear, like any mechanic part.

Static multifunctional cowls prevent these inconveniences due to the fact they do not have moving parts, even though they have been carefully analysed to maintain an optimal forced draft, in case of winds too.

The shape of this chimney cap, in fact, exploits the air flows the chimney is exposed to and, through the Venturi Effect, it creates a depression inside the flue by enhancing its draft.

Therefore, these multifunctional cowls associate a quite common shape (similar to spires on top of many churches) with an avant-garde technology, in order to activate the flue draft process naturally.

These terminals are made of 304 stainless steel which can be polished, opaque or bronzed, in order to look like aged copper. On commission, it is possible to have them in different materials too. The structure of these chimney cowls can be seen in the picture on the left.

These terminals are made of 304 stainless steel which can be polished, opaque or bronzed, in order to look like aged copper. On commission, it is possible to have them in different materials too. The structure of these chimney cowls can be seen in the picture on the left.

Cowls are equipped with deflectors designed to clear out the smoke and funnel the air flows, in order not to cause smoke returns at fireplace level.