The kitchen, as well as the bathroom and the laundry room are the rooms that are most affected by this problem since much of the moisture that forms inside our homes is due to the water vapor produced in these rooms.

On the one hand we have the kitchen where food is cooked, on the other hand we have the bathroom where large quantities of water are used for personal hygiene, and finally we have the laundry room where laundry is washed and dried.

A family of four, at a rough calculation, discharges into the atmosphere up to 15 liters of water per day in the form of water vapor.

Paradoxically, modern houses, which are better insulated, can be prone to condensation problems due to the lack of breathability of the walls and the inefficiency of windows and doors.

If the house is poorly insulated, moisture will escape through the walls and cracks, but if you have protected your home against the weather you will have sealed these outlets as well and the moisture will tend to accumulate and condense on the walls and windows, causing peeling paint, swelling of wooden furniture and mold.

The problem can be solved by ensuring that the right level of humidity is maintained inside the home and this can only be done by ensuring proper air circulation.

It is therefore necessary to install extractor fans that expel moisture from the rooms where it is produced most: the kitchen, the bathroom and the laundry room.

In order to install the aerators it is necessary to make holes in the perimeter walls or in the window frames.

The second option is now almost completely obsolete. Once it might have made sense to drill holes in the glass, but nowadays, with double or triple glazing, it would destroy the energy efficiency of the window.

The optimal humidity in the home

Living in a healthy environment does not mean living in a humidity-free environment, we need humidity to live since our tissues are largely composed of water.

If the fight against mold, therefore, must be conducted without quarter, even an excessive dryness of the air is not to be pursued, on the contrary.

A humidity level below 40% is just as uncomfortable as a humidity level above 70%; a humidity level around 50-55% should be considered optimal.

In order to guarantee optimal humidity levels at all times, ventilation devices must be installed that are equipped with sensors and can therefore be activated automatically as needed.

Extractors fans are classified on the basis of the diameter of the fan and the number of revolutions per minute; the larger the fan and the faster it turns, the more air is sucked in per hour.

Position and size of ventilation holes

When we open the window, there is a natural exchange of air between inside and outside, the stale air of the house escapes and fresh air (if we do not live in the city) enters from outside.

Airing and ventilation holes act in the same way: as permanent openings in the outer walls that ensure air circulation.

Especially in the kitchen, where gas burners consume air and cooking food involves the emission of steam and odors, it is mandatory that there are ventilation holes in the walls.

A certain amount of outside air must be able to enter the kitchen to compensate for the air consumed by the burners and that expelled through the hood and thus avoid depressions that would cause air to stagnate in the house, with consequences also on neighboring rooms, causing, for example, problems of chimney draught.

The position of the ventilation and suction holes must be opposite: the air suction hole from the inside to the outside must be placed at the top, on a perimeter wall, the ventilation hole must be placed at the bottom, always on a wall facing the outside.

It is not necessary for the holes to be placed on the same wall but they must both have access to an external space.

On the contrary, it can be said that the ideal location of a ventilation hole is as high as possible, on the wall, perhaps in front of a door or a window, so that the incoming air crosses the whole room before being expelled, thus ensuring the best possible recirculation inside the home.

As for the size of the holes, it is always better to get advice from a technician because it can vary depending on the rooms, their size, the presence of boilers and burners, etc..

The electric heat recovery devices

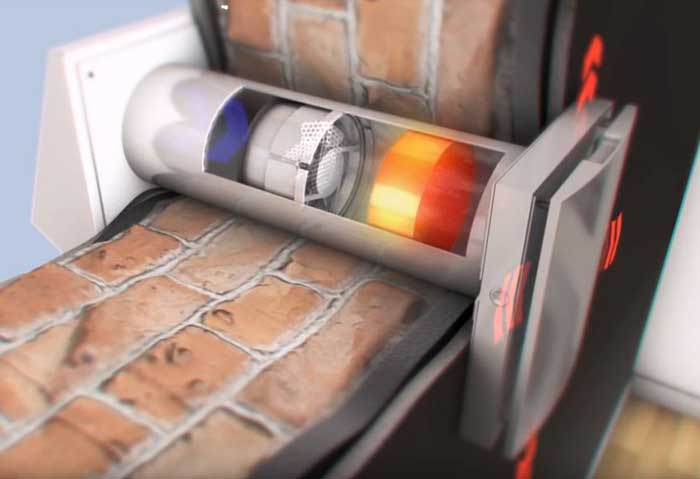

The most modern extractor fans are those that include heat recovery.

If the traditional systems of aeration and aspiration guaranteed the right recycling of the air, it is also true that this happened bringing an inflow of fresh air from the outside towards the inside.

Obviously, the cold air from outside decreased the temperature in the domestic environment with consequent greater expenditure of energy for heating.

Basically, it was like having windows open all the time, with all the consequences.

For this reason, systems have been developed that, through a single hole, guarantee to expel stale air and humidity from the environment and simultaneously, or alternately, introduce air from outside to inside.

This, on the surface, would seem to be a system rather similar to the traditional ones, perhaps bringing everything together in a single hole.

Heat recovery, however, means that while the extractor fan expels air from the inside to the outside, this heats a ceramic plate of the component so that when air is introduced from the outside to the inside, it can heat up.

This allows the temperature of the rooms to be kept constant as well as the degree of humidity.

Installing a wall mounted heat recovery device

Installing a wall an extractor fan requires only a few hours of work and, in principle, could even be a job within the reach of the DIY enthusiast.

In practice, however, you need some essential tools such as a wall cutter to be mounted on a fairly powerful dowel.

With regard to the hole, therefore, it is better to turn to specialized personnel especially if you are not equipped with the right equipment.

Before making the hole, however, we must ensure that in the area of the wall where we are going to create the hole do not run electrical wires or other pipes, to do this an indispensable tool is the cable detector of which we have spoken in a separate article.

Once the hole has been made to measure for the heat recovery device we are going to install, all that remains is to follow the manufacturer's assembly instructions.

The external grill of the heat recovery device can also be installed from the inside, fortunately, and this will avoid us the need to mount expensive external scaffolding to get to the desired point.

The trickiest part is the electrical connection.

Almost certainly at the top of the wall, where heat recovery devices are normally installed, you will not have an electrical outlet available, so you will have to derive some cables from the nearest electrical outlet and then, by means of external ducts, bring them up to the vacuum cleaner.

Once connected to the mains, the heat recovery device can be managed by a convenient remote control that will allow us to control the ventilation and suction phases and also to set the desired air humidity level, so that the heat recovery system can start automatically to restore the ideal environmental conditions.

Acoustic insulation of ventilation holes

The walls of modern houses are usually composed of three layers: an outer wall, a layer of insulation material, and an inner wall.

When we open a hole in the wall to install an air vent, we are essentially opening a gap through which outside noise can penetrate into our home.

This, added to the noise of the fan, even if very low, can be a source of discomfort and decrease the quality of life in our home.

In short, if we want to solve the problem of humidity and mold in the house, we would not want to end up with a problem of excessive noise, right?

The problem is not easily solved if we operate in the post-construction phase of the building.

If our house overlooks a busy street and a very noisy environment, before opening a hole to install a heat recovery ventilator, we must begin to understand, from the outset, how to avoid the problem of noise that could filter through the holes.

Basically, to get around the problem you need to insulate the aerator.

On the market there are products made specifically for this purpose including, as an informative note, the Sil-block, Rumor Block, Silentio; the latter product is a kind of diverter that allows you to dislocate the inlet and outlet holes in different positions.